KLFJX forced circulation pump

- Tel:13955093008

- Email:13955093008@139.com

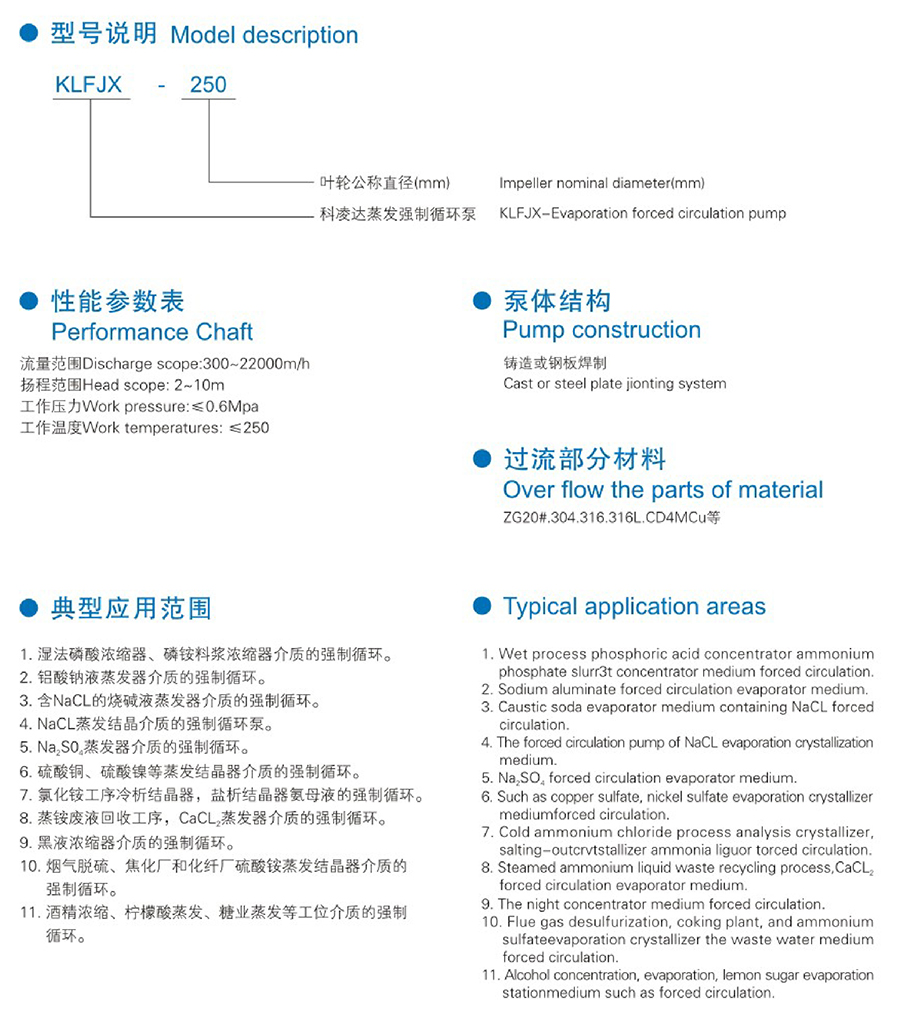

Description

summarize

KLFJX series axial flow evaporation forced circulation pump is a large-flow, low-head axial flow pump jointly designed and developed by our company and Shanghai Fanfang Pump Technology Co., LTD. Introduce and digest the advantages of similar products at home and abroad, optimize the design of the product, and ensure the reliability, economy and safety of the product. The pump adopts international standard manufacturing, effective energy saving, stable performance, reliable, easy maintenance. The product is widely used in chemical industry, non-ferrous metals, salt making, light industry and other industries are evaporation, crystallization, chemical reaction and other processes.

Structural characteristics

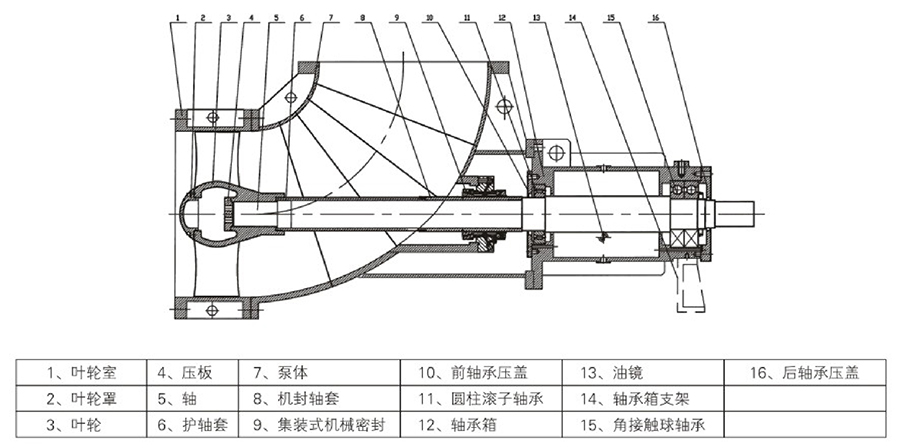

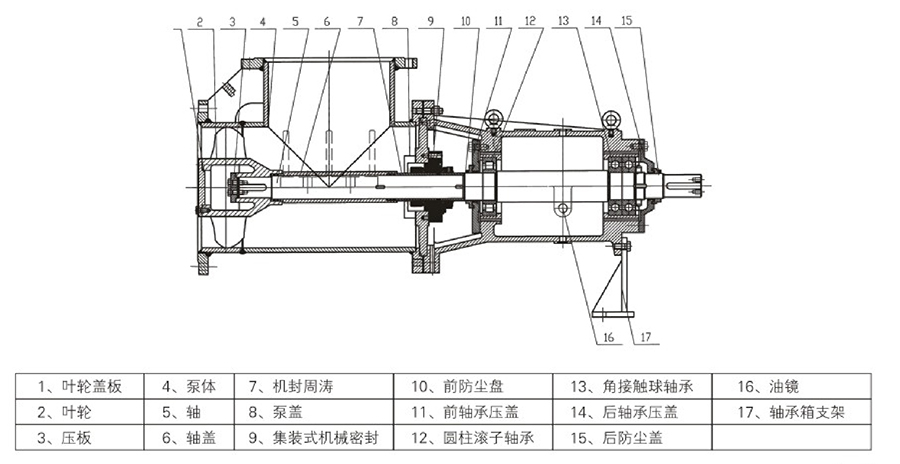

KLFJX series axial flow evaporation forced circulation pump is mainly composed of impeller, pump body, auxiliary impeller, sealing box, middle support, bearing box components, bearings and other parts.

1, pump body center support: compared with the pump body support type, the rotor heat neutral is good.

2, cantilever rotor: compared with the double support type, the number of shaft seals is halved, the pump is light in weight, small in size, and easy to repair.

3, the pump efficiency is high, the effective area is wide: by changing the blade installation Angle, changing the paraphrase two methods, to meet the user's requirements for flow, head and make the pump running station in the effective area, the energy saving effect is significant.

4, good anti-cavitation performance: suitable for low level evaporator, greatly reduce the evaporation plant investment. It is also suitable for new evaporators with heating chambers with high fluid resistance on the pump inlet side (reverse circulation evaporator, double heating chamber series evaporator).

5, low speed type: the pump runs smoothly; The flow parts wear light, long life; Low crystal breakage, suitable for evaporation crystallization process.

6, the rear door structure: do not need to remove the pump body inlet and outlet flange of the pipeline connection, you can extract the rotor, easy maintenance, rapid.

7, shaft seal: the use of dynamic and dynamic structure assembly to ensure that the pump will not leak when working and stationary, the power seal uses the auxiliary impeller seal, the static seal uses the packing seal and mechanical seal, mechanical seal, mechanical seal is divided into single end and double single-sided two, for selection.

8, evaporator no expansion joint: can be elastic pump base or suspended pump, heat compensation is reliable, reduce evaporator investment.

9. High reliability of the whole machine: high strength of the pump shaft, large bearing capacity, water cooling sleeve of the bearing seat, long life of the shaft seal, good material performance, to ensure that the single machine jump operation effect is good.

10. Rotation mode:

Direct connection: direct connection between pump and motor over wound coupling {code D).

Belt transfer: Through the triangular belt rotation, change the speed to adjust pump performance easily (code V).

Reducer: Reduced speed through the gearbox, suitable for high-power pumps (code G).