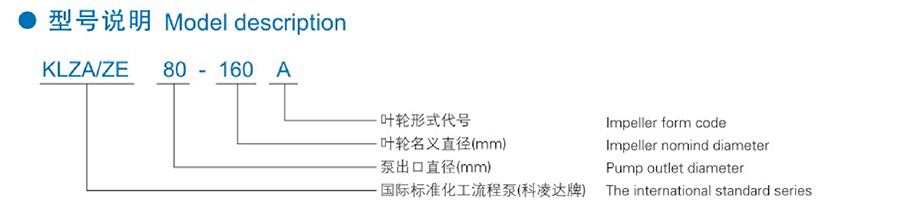

KLZA/ZE type chemical process pump

- Tel:13955093008

- Email:13955093008@139.com

Description

summarize

KLZAZE type petrochemical process pump is a single-stage horizontal centrifugal pump, which is designed and manufactured by our company according to the American Petroleum Institute AP1610 standard and VDMA24297(light, medium and heavy duty) specifications, and optimized and improved on the basis of the original ZA type pump, effectively improving the reliability of the product; The pump body of the KLZA type pump is the foot support that is OH1 type structure in the standard, and the KLZE type pump is the center support that is OH2 type structure in the standard. The basic structure of the impeller is closed structure, and it can be designed as open or fully open structure according to the characteristics of the conveyed medium. Axial suction, radial discharge. According to the working conditions, the hydraulic balance is carried out by the front and back wear rings and balance holes. The shaft seal adopts packing seal, single end machine seal or double end machine seal, and provides circulation system for cooling, flushing or sealing fluid.

Pressure class: KLZA type pump design pressure of 2.5Mpa, KLZE type pump design pressure of 5.0Mpa.

Standard piping is designed according to AP1610 specification. Suction and discharge pipe flanges have the same pressure rating.

The working direction of the pump: from the driving motor end, the steering of the pump rotates in a clockwise direction.

Scope of application

KLZA/ZE series pumps are suitable for conveying a variety of neutral and corrosive liquids (acids, alkalis, salts and liquid petrochemical products, organic compounds, etc., of various concentrations and temperatures), the temperature range is -80° C ~450 ° C, the maximum use pressure KLZA type up to 2.5Mpa, KLZE type up to 5.0Mpa.

The range of products is widely used in:

1, refining, petrochemical industry engineering;

2, coal processing industry and low temperature engineering;

3. Chemical industry, paper making, sugar industry, food processing and general process industry;

4, water supply, desalination, power generation, heating and air conditioning system engineering;

5, environmental protection engineering, water treatment, shipbuilding and offshore industry engineering, etc.

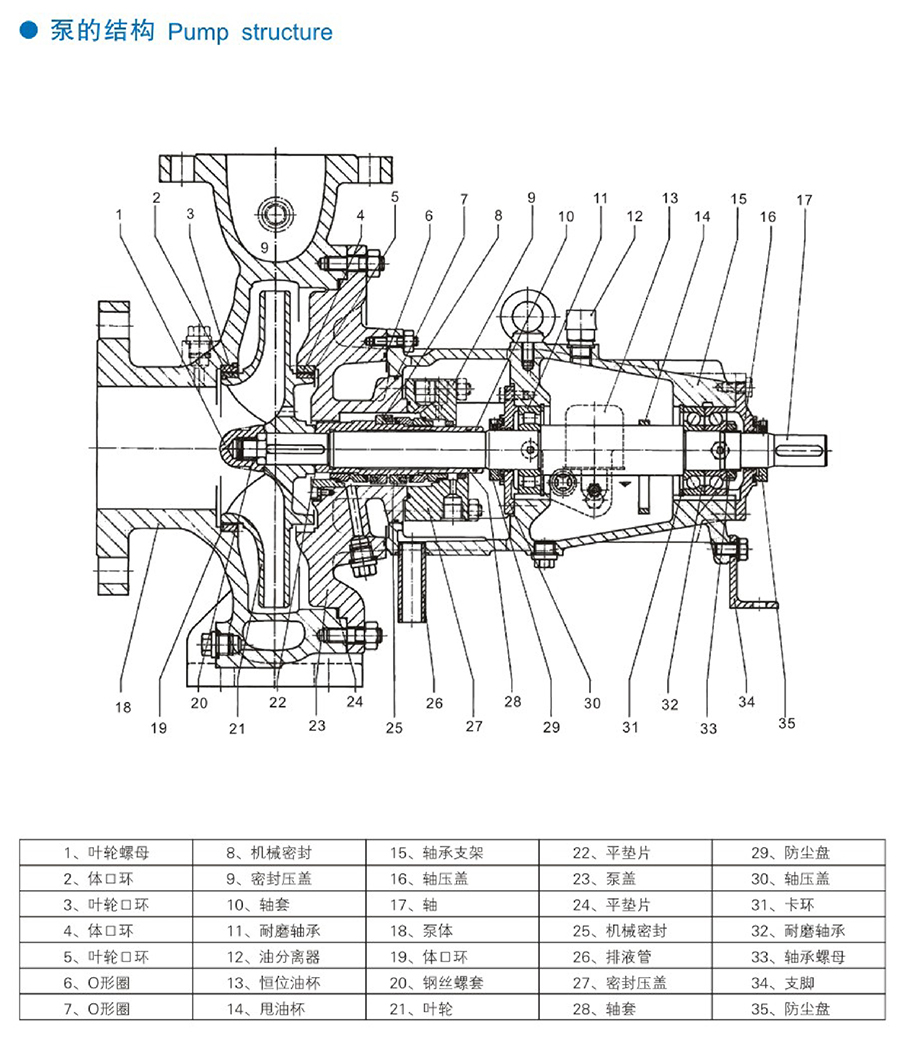

Structural characteristics

KLZAIZE type petrochemical process pump is a single stage horizontal centrifugal pump, axial horizontal suction, vertical radial top discharge, sealing cavity is set outside the jacket, can pass steam or coolant, to achieve insulation or cooling cooling effect.

1, bearing suspension body has three structural forms: heat sink natural cooling mode (-80℃-120 ℃) heat sink and fan joint cooling mode (120℃~220℃) water cooling mode (above 220℃).

2, the pump for the rear open-door structure, easy maintenance and repair, while ensuring the process of work requirements of the maintenance conditions, bearing, shaft seal and impeller for a rotor assembly can be quickly disassembled or assembled, greatly shortening the parking maintenance cycle.

3, the impeller of the pump is a single suction radial closed, with impeller wear ring and pump body wear ring, after wear only need to replace the wear ring can reduce the cost of maintenance and components.

4, the impeller of the pump is a single suction radial open type, the pump body or pump cover is provided with a liner to adjust the clearance with the impeller, to ensure the working performance of the pump and improve the efficiency of the pump.

5, the pump shaft seal has two types of packing seal and mechanical seal (single end machine seal and double end machine seal), the user can choose according to different working conditions. Circulation systems for cooling, flushing or sealing fluids can also be set up.

6. The bearing is lubricated with lubricating oil, and the bearing suspension body is equipped with constant oil cups and oil labels;

7, pump and motor with extended diaphragm coupling connected transmission, can compensate for small axial, radial and angular displacement, while convenient for pump maintenance and maintenance work, reduce labor intensity, save time, improve work efficiency.